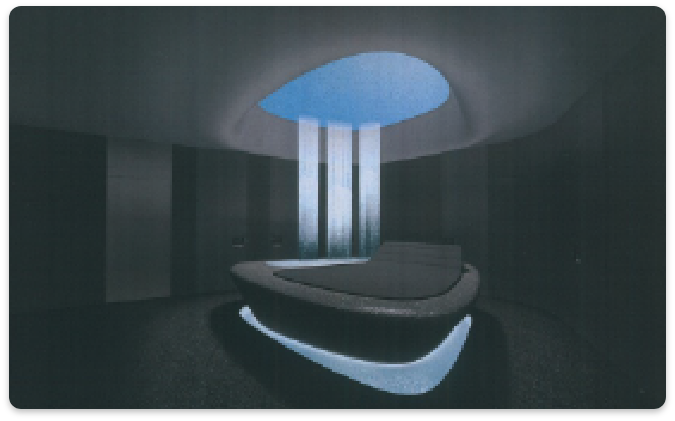

WATER PORTAL TO ANOTHER WORLD

Embracing the Philosophy: If It Can Be Done, It Must Be Done

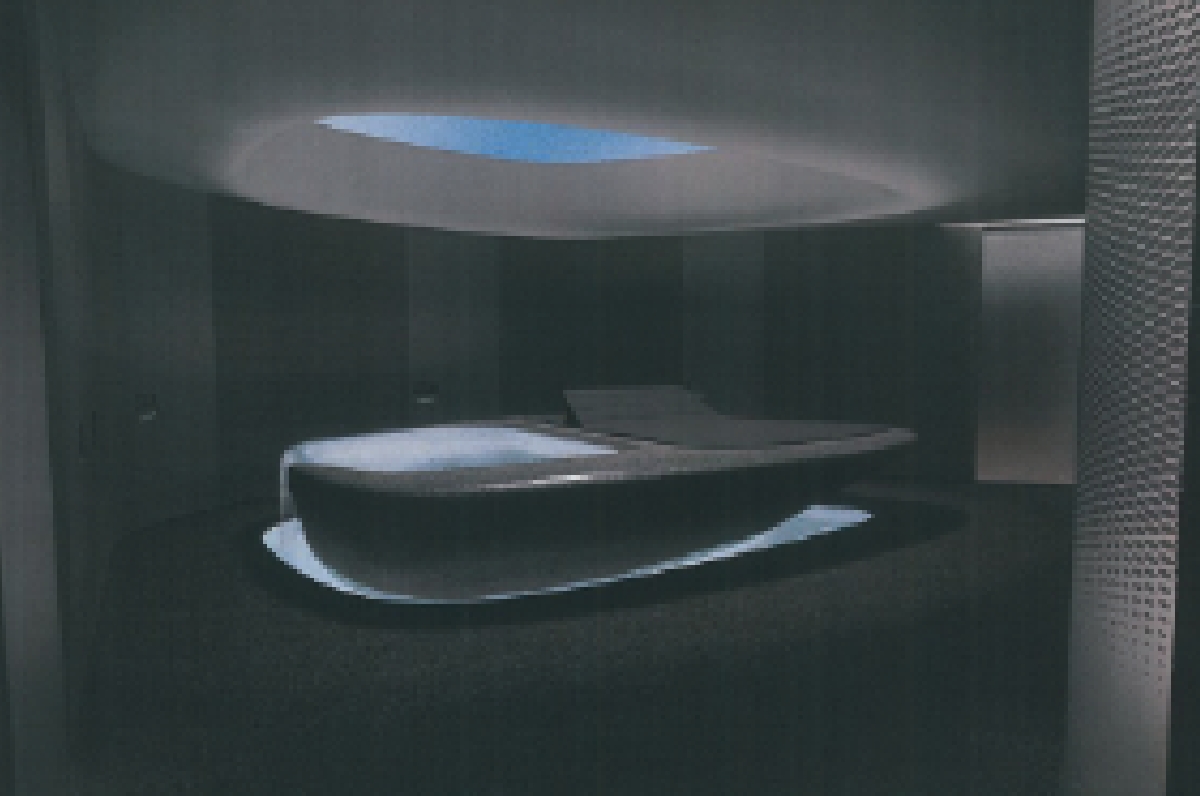

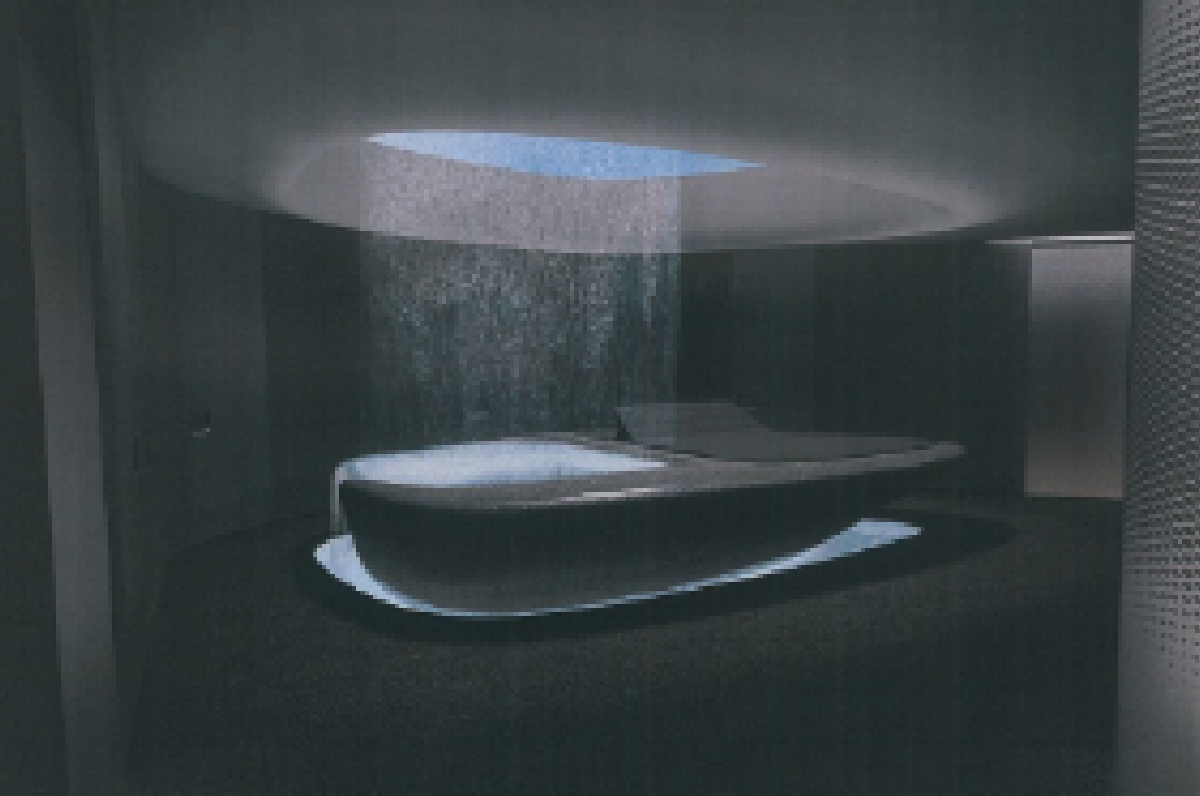

The creators of the spaceship house, on a quest for cutting-edge bath technology, soon realized the need for an innovative shower solution. Their vision: a concept that emulated everything from a light London drizzle to a torrential downpour. At Unique Automation, our engineers thrive on such challenges, and this project was no exception, sparking creativity from the outset.

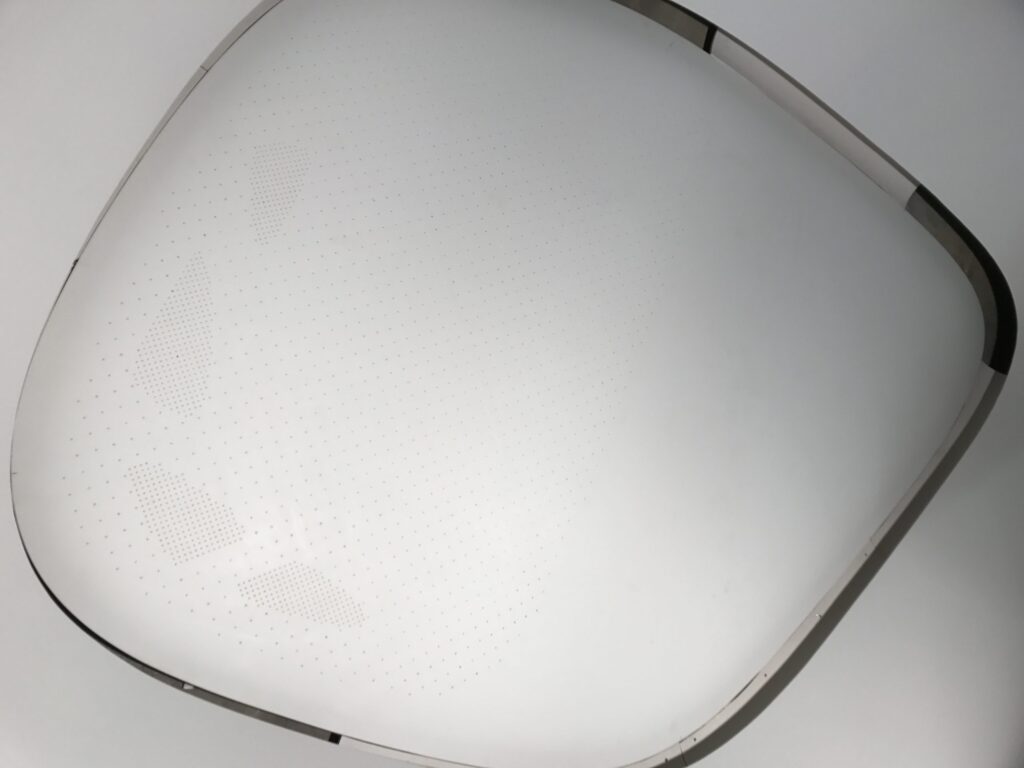

We embarked on creating specialized tooling and crafting the first prototypes of rain nozzles cluster. With the architectural studio’s impeccable reputation at stake, only the highest standards were acceptable. After rigorous testing and approval of the prototype rain performance, we were ready to progress. However, unforeseen events led to a significant reduction in the allocated space for the SkyShower, shrinking the ceiling drop from 600mm to a mere 65mm. This called for a complete redesign, a task complicated by the nuances of managing water flow, including considerations like gravity and temperature loss.

Testing in London under 6bar pressure ensured optimal performance at a maximum flow of 600 litres per minute. Yet, the challenge intensified when the on-site water supply was limited to a hose with negligible pressure. The installation process was equally fascinating and demanding. With the SkyShower’s components weighing several hundred kilograms each and the adhesive setting rapidly, precision was crucial. The reduced installation space left a margin of less than 5mm, demanding meticulous scribing and gluing. The precision of the nozzles and their integral role in the SkyShower meant errors could be costly, with over-sanding leading to droplet misformation and insufficient polishing resulting in visible imperfections.

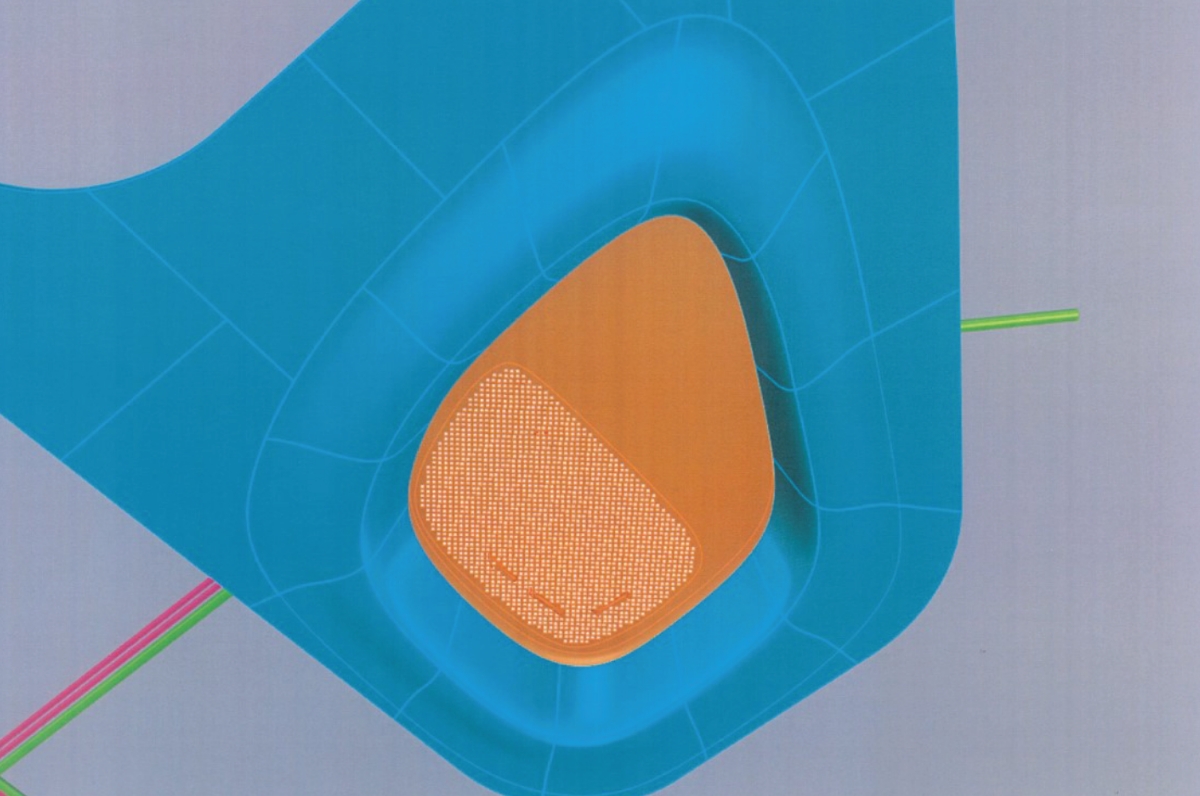

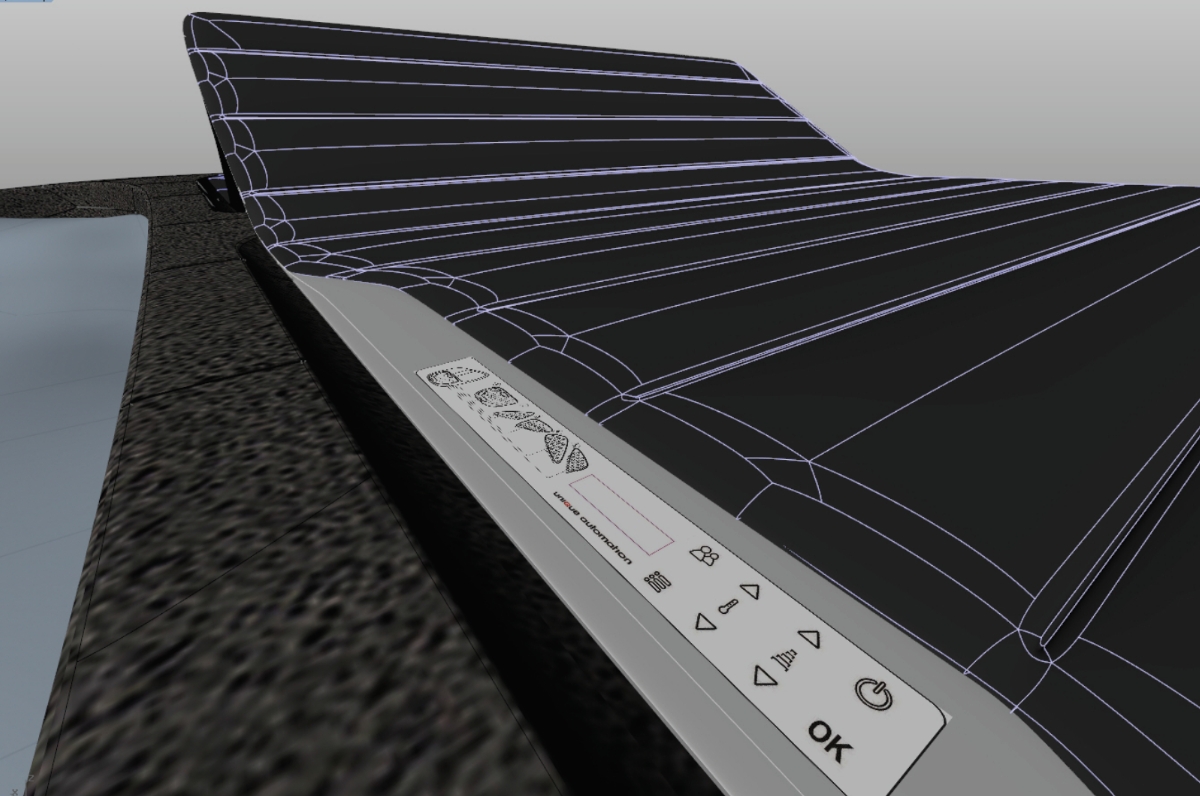

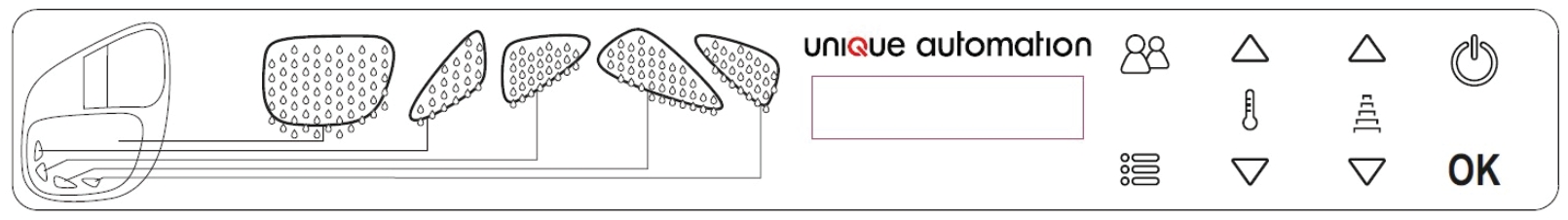

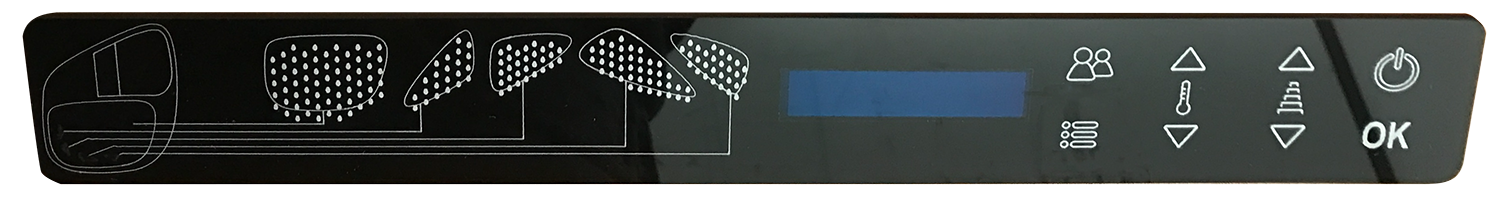

The interface of this impressive rain feature evolved into a unique and bespoke solution. Initially, the design underwent various iterations, eventually crystallizing into a form that truly represented its essence. One of the toughest tasks for our engineers was limiting choice – a departure from their usual role of expanding possibilities. However, the architectural team’s wisdom in streamlining the rain intensity options to three defaults encapsulated a broad range of experiences without overwhelming users.

The project, revisited and commissioned to meet the customer’s approval long after the initial installation, stands as a testament to our commitment to delivering extraordinary experiences. Nearly a decade later, we look back with pride, hoping that the SkyShower continues to provide the mesmerizing experience it was designed for.

The interaface

Facing the SkyShower project, our key challenges included reimagining a grand vision within significantly reduced spatial constraints, shrinking from 600mm to just 65mm. This necessitated a complex redesign, balancing the intricate dynamics of water flow and temperature control within a confined space. Additionally, adapting to the limited on-site water supply, far below the required 6bar pressure, tested our engineering ingenuity. The precision-driven installation process, with weighty components and minimal margin for error, further amplified the complexity, demanding exceptional accuracy and attention to detail. The rest was just electronics