A BATH IN AN INSTANT

The Quest for the Perfect Bath in Under One Minute

In early 2010, we were approached by an architectural firm with a rather unique challenge. Their brief, while a bit loose, hinted at either towering ambition or mere whimsy. After a deep-dive discussion with the lead architect, it became abundantly clear – this was an ambitious endeavour.

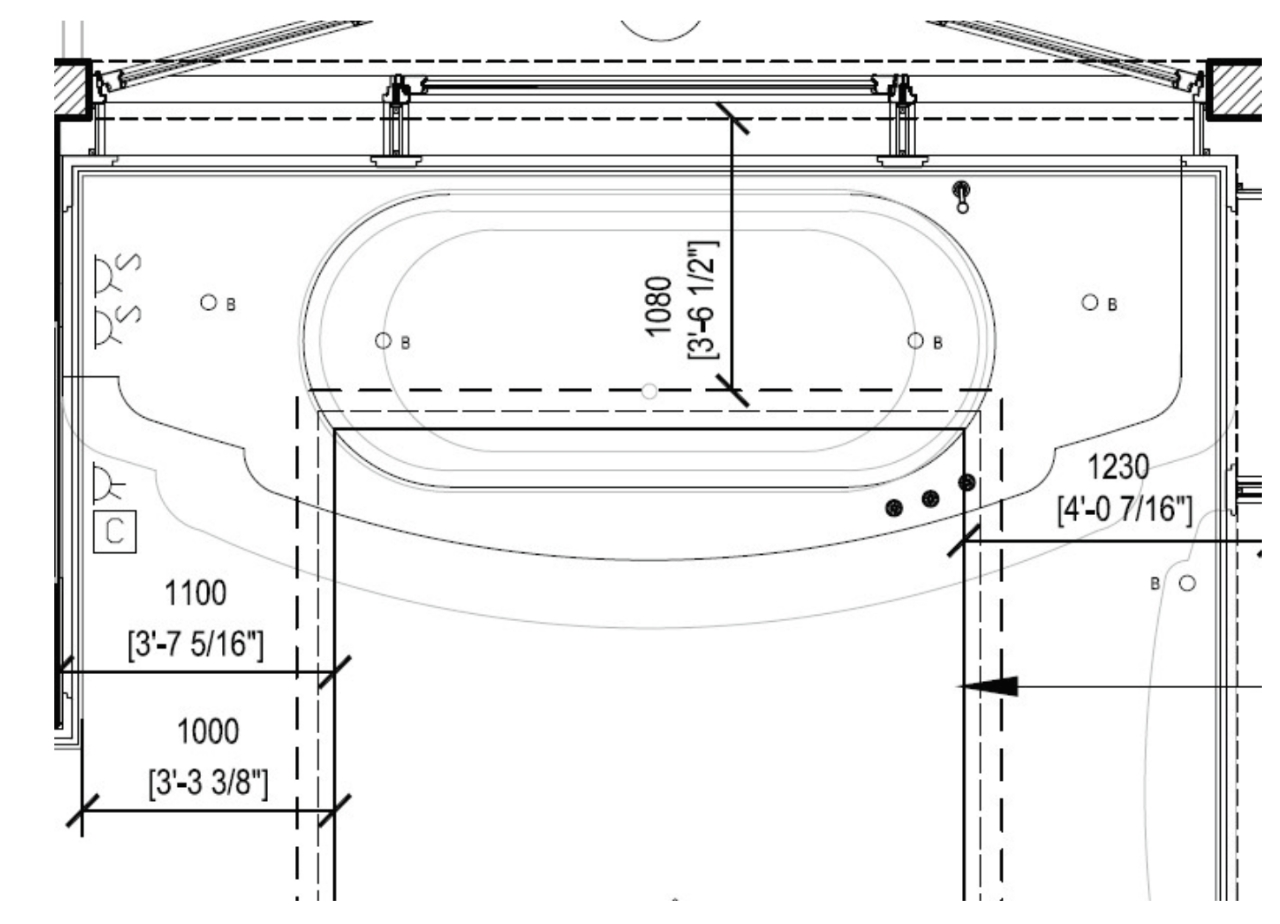

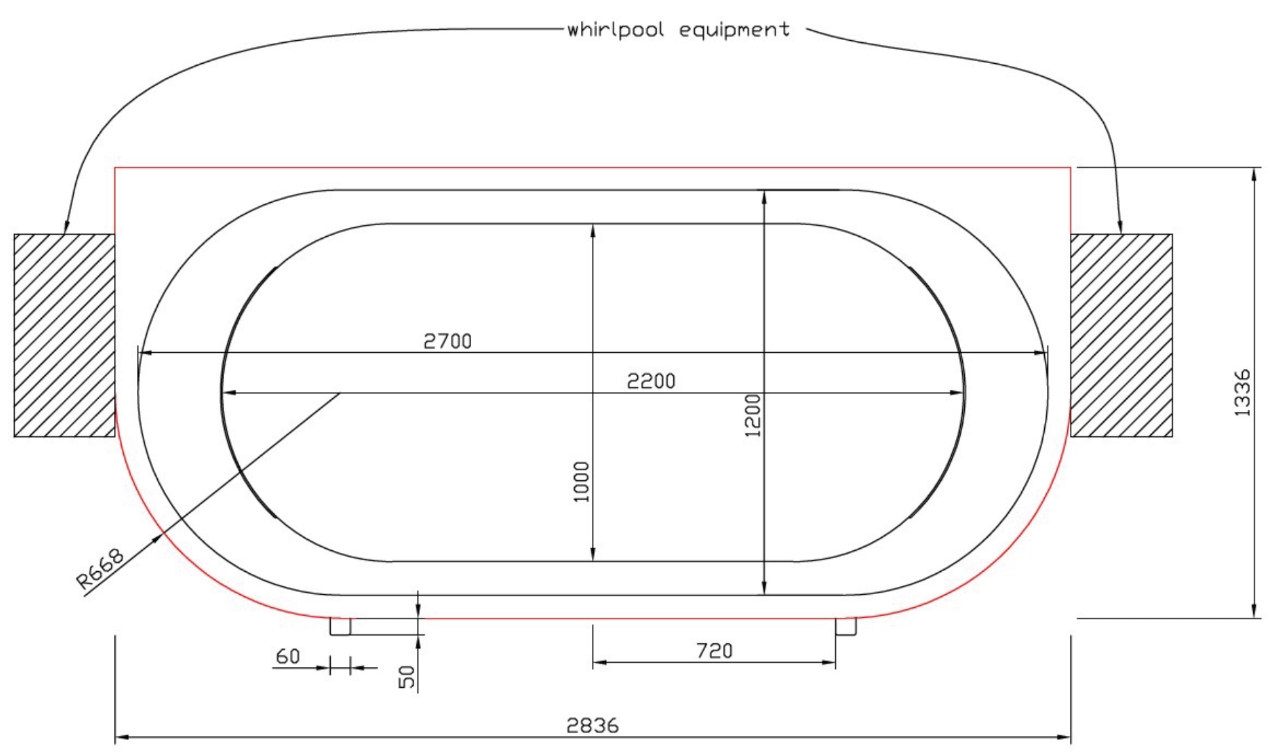

“The bath needs to dominate,” the architect elucidated, emphasizing its pivotal role in a sizable bathroom. At that juncture, we were delving into the world of Corian fabrication for baths. Their request? Not only a substantial size but also a near-instant fill, topped off with a whirlpool system that packed a punch.

Such challenges invigorate the mind. However, a technical hiccup emerged. The task? Delivering a staggering of water in a mere 60 seconds. Our workaround entailed deploying a 2” pipework for both hot and cold supply, and a sprinkle of hope.365 US gallons

As 2010 drew to a close, our masterpiece – a grandiose Corian bath – was prepped and crated, destined for the USA. It was a sight to behold, complete with Corian jets and ingeniously designed fillers and drains concealed within shadow gaps. While we narrowly missed the ambitious one-minute target, the client’s satisfaction more than compensated for those extra seconds.

Over six months of design and production, multiple consultations ensued. To ensure optimal comfort, we even shipped a prototype for the client’s approval. It’s akin to test-driving a car before purchase, albeit, in this case, a waterless preview.

Our gratitude to those who dare to dream big. To our client and the architects, a heartfelt thank you. Their vision led to numerous firsts: our inaugural Corian bath production and a proprietary bathomatic whirlpool controller, among others. While not about revolutionary technology, it’s about applying innovation to everyday challenges.

Now, the client enjoys a bath reminiscent of an arctic snow sculpture. Warm to the touch, quick-filling, and with a whirlpool roar rivalling the majestic Niagara. Remarkably, only in 2022, after a dozen years, did the bathomatic system need its first servicing – a testament to our commitment to durability and excellence.

Challenges: Designing and manufacturing a bath large enough to dominate the space, yet capable of filling almost instantly, was a significant hurdle. Though Corian is strong, its brittleness makes it prone to breaking. The bath’s frame had to support the immense weight and accommodate material expansion and contraction without compromising structural integrity. Furthermore, integrating body and air jets into this brittle material reduced its strength and necessitated additional support. The customer’s request for a powerful massaging function required the installation of large jet pumps, increasing complexity. Rapid filling was another challenge, solved by implementing advanced 2” pipework for both hot and cold water supply. Integrating a dynamic whirlpool system into the Corian structure, while maintaining aesthetic elegance and functional efficiency, presented a complex design and engineering challenge. Balancing the need for service accessibility, structural support, and invisibility made this project particularly challenging, yet it was also intriguing and rewarding